Butt Table

A Butt Table is a table made from the butt slices of a tree. Here is one way to make yourself a butt table.

What's a Butt Table ??

A picture is worth a thousand words . . .

Architecture

The butt table presented here consists of three basic parts:

1) The table top (or butt)

2) The stand

3) The "feet"

1) The table top (or butt)

2) The stand

3) The "feet"

Tools and Materials

Tools that were used for this project

- Electric chain saw (about $50)

- Alternative to chain saw: reciprocating saw

- Chisels (be sure to buy chisels that are already sharpened)

- Electric sander

- Jig saw

- Dremel tool

- Drill

- Nail gun

- Large stump for the table top

- Thick branch for the stand

- Medium thickness branch for the feet

- 150 and 220 grit sandpaper (lots)

- Oil-based stain

- Satin polyurethane

- 2 and 3 inch screws

Terminology

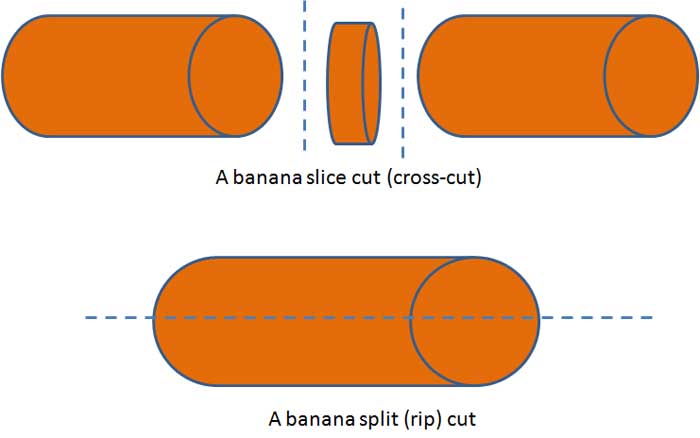

Banana cut or slice: A round slice taken out of a branch, much like the way you slice a banana for a peanut butter sandwich.

Banana split: A length wise split down a branch, much like the way you cut a banana length-wise for a banana split. Some people also refer to these as rip cuts.

Butt table slice: Same as a banana cut , but taken out of a trunk rather than just a branch.

Crotch: A limb containing a branch that shoots out at a good angle for making a hook. Warning: a crotch stick can be rather itchy, though. (thanks to spanner1969 and anabelle)

Banana split: A length wise split down a branch, much like the way you cut a banana length-wise for a banana split. Some people also refer to these as rip cuts.

Butt table slice: Same as a banana cut , but taken out of a trunk rather than just a branch.

Crotch: A limb containing a branch that shoots out at a good angle for making a hook. Warning: a crotch stick can be rather itchy, though. (thanks to spanner1969 and anabelle)

Step 1: Cut Down a Tree

See the Instructable "Cutting Down a Tree in Pieces"

Table Top: Mark the Slab Width on Trunk (1 Min)

The table top is a large banana slab sliced from a tree trunk using a chain saw or reciprocating saw.

To help keep the resulting slab somewhat the same depth all around, first mark the depth all around the trunk. This will help keep your cut straight. A little.

To help keep the resulting slab somewhat the same depth all around, first mark the depth all around the trunk. This will help keep your cut straight. A little.

Table Top: Do the Cut Thang (2 Hrs)

I recommend a chain saw for this. Cut along your mark and take your time.

NOTE:

Wear eye goggles and ear plugs!

NOTE:

Wear eye goggles and ear plugs!

TIP: Ear Plugs

I recommend the ear plugs that go around your neck so that you can remove them and not have to try to find them over and over and over.

Been there.

Done that.

Been there.

Done that.

Table Top: Raw Slab

The final slab may be uneven and choppy.

Table Top: Plane (2 Hrs)

After cutting off the butt slab, you may need to smooth out the choppiness of the saw marks and help even it out.

For this I recommend an electric planer. (I wish I had known there was such thing as an electric planer a long time ago.)

You can also use a chisel or hand planer. If you use a hand planer I'd recommend using a workmate or similar type of bench/stand with dogs.

NOTE:

Here is a great Instructable with an alternative (and smarter) way to level off your butt:

https://www.instructables.com/id/Jig-for-surfacing-with-a-router

For this I recommend an electric planer. (I wish I had known there was such thing as an electric planer a long time ago.)

You can also use a chisel or hand planer. If you use a hand planer I'd recommend using a workmate or similar type of bench/stand with dogs.

NOTE:

Here is a great Instructable with an alternative (and smarter) way to level off your butt:

https://www.instructables.com/id/Jig-for-surfacing-with-a-router

TIP: $@*#! Plane Away From Plastic Bags

TIP: When planing with an electric planer, be sure to let the thing stop before putting it near plastic bags.

Tip: Work Bench and Bench Dogs

Planing Tip:

If you use a planer, you might want to engage a WorkMate-style workbench with bench dogs to hold down the slab.

If you use a planer, you might want to engage a WorkMate-style workbench with bench dogs to hold down the slab.

Table Top: Sand (1 Hr)

Sand down the butt slab with sandpaper. You'll probably need to start with 100 (or less), then 150 and 220 grits.

Note:

I'd recommend an electric sander but NOT a battery-powered sander because you will run down the battery excessively and be constantly re-charging it. A battery-powered sander is just not a good tool for butt sanding.

Note:

I'd recommend an electric sander but NOT a battery-powered sander because you will run down the battery excessively and be constantly re-charging it. A battery-powered sander is just not a good tool for butt sanding.

Table Top: Alcohol Bath (optional)

No not THAT kind of alcohol bath!

To help keep the slab's cracks (hee hee) from splitting, you might want to soak the table top for a few days in a bath of denatured alcohol.

An easy (sort of) way to do this is to place the slab into a plastic trash bag, add three or four cans of alcohol and place the whole thing in a plastic bin.

Or you can just skip this step.

To help keep the slab's cracks (hee hee) from splitting, you might want to soak the table top for a few days in a bath of denatured alcohol.

An easy (sort of) way to do this is to place the slab into a plastic trash bag, add three or four cans of alcohol and place the whole thing in a plastic bin.

Or you can just skip this step.

Table Top: Crack (hee Hee) Filling (optional)

Another or additional way to deal with slab cracks (hee hee) is to create a mixture of saw dust and wood glue (as a type of putty) and shove it into the cracks (hee hee).

Also, here is an instructable for more thorough crack (hee hee) filling:

https://www.instructables.com/id/Repairing-Split-Wood/

Also, here is an instructable for more thorough crack (hee hee) filling:

https://www.instructables.com/id/Repairing-Split-Wood/

Table Top: Staining Prep (5 Min)

I recommend staining and sealing the table top early on because otherwise it will get dirty and you'll have to go back and re-sand it after completing the other steps.

Be sure to wipe down the slab with denatured alcohol. Canned air can also be helpful to remove dust particles from the smaller cracks (hee hee).

Be sure to wipe down the slab with denatured alcohol. Canned air can also be helpful to remove dust particles from the smaller cracks (hee hee).

Table Top: Staining, Cont. (5 Min + Dry Time)

I use either a sponge brush and/or an old towel to apply and wipe, depending on which is closer to where I happen to be sitting at the time.

I usually use two or three coats of stain, depending on how crappy the first layer turned out.

I usually use two or three coats of stain, depending on how crappy the first layer turned out.

TIP: Staining

Tip 1:

Tap a few holes in the inner lip of the stain can (with a hammer and nail) when you first open it. This will allow the stain to drip back into the can on its own and will make it a little easier to close the lid and re-open it at a later time. Sort of.

Tip 2:

"They" say to sand lightly between coats of stain (and urethane), but all that has ever done for me is scratch up the surface (even with 2000 grit sandpaper). Plus it means I have to wipe off more sand dust. So, eh whatever.

Tip 3:

You might consider applying a wood pre-conditioner. Wood pre-conditioner is supposed to help the stain to seep into the wood consistently. I've never gotten much out of these products except an extra $15 or so on my credit card charges, so perform this step if you'd like to experiment with it.

Tap a few holes in the inner lip of the stain can (with a hammer and nail) when you first open it. This will allow the stain to drip back into the can on its own and will make it a little easier to close the lid and re-open it at a later time. Sort of.

Tip 2:

"They" say to sand lightly between coats of stain (and urethane), but all that has ever done for me is scratch up the surface (even with 2000 grit sandpaper). Plus it means I have to wipe off more sand dust. So, eh whatever.

Tip 3:

You might consider applying a wood pre-conditioner. Wood pre-conditioner is supposed to help the stain to seep into the wood consistently. I've never gotten much out of these products except an extra $15 or so on my credit card charges, so perform this step if you'd like to experiment with it.

Table Top: Polyurethane (5 Min + Dry Time)

Add two or three coats of polyethylene, er I mean polypropylene, er I mean polywallydoodle, er i mean pollywannacracker, er polyurethane.

Tip 1:

Be sure to mix this stuff up before using!

Tip 2:

As you apply it (I use a sponge brush) watch carefully for lil' tiny bubbles that will show up on the slab; go over them (the bubbles) again with your brush if you see them. After all, you don't want to end up with a bubble butt table top.

Tip 1:

Be sure to mix this stuff up before using!

Tip 2:

As you apply it (I use a sponge brush) watch carefully for lil' tiny bubbles that will show up on the slab; go over them (the bubbles) again with your brush if you see them. After all, you don't want to end up with a bubble butt table top.

Table Top: Final

Done with the butt, now on to the stand . . .

Stand: Size

Find a substantial, thick, straight branch for the stand.

Here I used a branch that I'll cut to about 30 inches high, with two children branchettes near its top to use for more support.

Here I used a branch that I'll cut to about 30 inches high, with two children branchettes near its top to use for more support.

Stand: Strip Bark (if Needed) (1 Hr)

Strip the bark off of the stand.

Tip 1:

A sharp chisel works better than a dull chisel.

Tip 2:

A tetanus shot is advised if you are a klutz. ahem.

Tip 1:

A sharp chisel works better than a dull chisel.

Tip 2:

A tetanus shot is advised if you are a klutz. ahem.

Stand: Cut (1 Hr)

Cut the branch to the height that you want your table to be.

I'd recommend a table saw for this task, but you could probably also use a reciprocating saw or even a circular saw if you have good balance.

Be sure to wear goggles and earplugs!

NOTE: T

The photo here demonstrates the stand and table saw positioning.

I'd recommend a table saw for this task, but you could probably also use a reciprocating saw or even a circular saw if you have good balance.

Be sure to wear goggles and earplugs!

NOTE: T

The photo here demonstrates the stand and table saw positioning.

TIP: Table Saw Deep Cuts

There's no easy way to do a deep cut, but one way to make it less not-so-easy is to make the cut in several passes.

Here, in this photo, you can see that the blade is set pretty low. Pass the branch through the blade, then raise the blade about a centimetre and go through it again, and so on.

Here, in this photo, you can see that the blade is set pretty low. Pass the branch through the blade, then raise the blade about a centimetre and go through it again, and so on.

TIP: Table Saw Goggles

I recommend the nerdy lab goggles that really wrap around your eyes and especially seal the bridge of your nose. The table saw kicks up a lot of dust and air that will otherwise slip under the other types of goggles. Or you can just close your eyes really tight.

Stand: Sand, Stain, Polyurethane (20 Min + Dry Time)

Wash, rinse, repeat the sanding, staining, polyurethaning steps for the stand.

Feet: Cut (1 Hr)

You'll want to rip-cut (or banana split) a thick branch to make two feet.

Make a mark along the length of the branch first to give you a rough idea of where you want the cut to be.

Note:

I haven't figured out the correct length that the feet should be but I had to make a new pair for this table because the feet were too short which rendered the table too unstable. If I find a good rule of thumb or if anyone knows of an equation to determine the best size feet, I'll update this step.

UPDATE:

Thanks to Instrucable member sconners for pointing out that the feet should probably be about as long as the diameter of your table top slab.

Make a mark along the length of the branch first to give you a rough idea of where you want the cut to be.

Note:

I haven't figured out the correct length that the feet should be but I had to make a new pair for this table because the feet were too short which rendered the table too unstable. If I find a good rule of thumb or if anyone knows of an equation to determine the best size feet, I'll update this step.

UPDATE:

Thanks to Instrucable member sconners for pointing out that the feet should probably be about as long as the diameter of your table top slab.

TIP: Table Saw Rip Cuts on Branches

Rip cutting on a table saw is usually done by placing the wood along the table saw's fence.

A tree branch is not perfectly straight though, so makes the job even more difficult.

When I split my feet, I used the same technique as cross-cutting the stand; namely by doing many passes. It took about 45 minutes to complete the rip cuts.

Tip 2:

Make yourself a rip stick: shown in the photos. At the tip of each of the claws of the rip stick is a pointy nail which helps grab on to the branch as you guide it through the blade. A normal push stick guides the branch from its back end. The fence keeps the branch from rolling away. Take your time and do several passes. After each pass, stop the blade, re-position the branch, then raise the blade and do another pass.

A tree branch is not perfectly straight though, so makes the job even more difficult.

When I split my feet, I used the same technique as cross-cutting the stand; namely by doing many passes. It took about 45 minutes to complete the rip cuts.

Tip 2:

Make yourself a rip stick: shown in the photos. At the tip of each of the claws of the rip stick is a pointy nail which helps grab on to the branch as you guide it through the blade. A normal push stick guides the branch from its back end. The fence keeps the branch from rolling away. Take your time and do several passes. After each pass, stop the blade, re-position the branch, then raise the blade and do another pass.

Feet: Cut Result

When finished cutting, your feet pieces will look something like this.

Feet: Put Side-by-side

Position the feet side by side, arranging them so that there is the fewest amount of distance between the two.

Feet: Place (temporary) Cross Braces Under Feet

Put a couple of cross-brace pieces of wood under the feet.

Feet: Attach Temporary Cross Braces (10 Min)

Flip the feet and cross brace over (carefully) and attach the cross braces to the bottom of the feet. This will be a temporary brace.

Use either a nail gun or screws to attach the cross braces.

Here, I used a nail gun but I recommend screws (you'll see why soon)

Hint:

Make sure that the nails or screws that you use to attach the braces are short enough so that they don't go through the top of the feet. Yep. Been there. Done that too. < sigh >

Use either a nail gun or screws to attach the cross braces.

Here, I used a nail gun but I recommend screws (you'll see why soon)

Hint:

Make sure that the nails or screws that you use to attach the braces are short enough so that they don't go through the top of the feet. Yep. Been there. Done that too. < sigh >

Feet: Create Template for Stand (1 Min)

Using a piece of thin cardboard, trace the stand onto the cardboard.

Feet: Stand Template Example

The template will look something like this.

Feet: UPDATED STEP

Thanks to Instructable member jbrecken for this note:

You'll have to use a pin or even a drill to mark the template's outline to its other side if you want to get a good fit and if your stand/branch is not very symmetrical.

Mine (my stand branch) was pretty symmetrical so I did not notice that the template was actually the mirror image of the outline when it is applied in to the bottom of the feet in the next step.

You'll have to use a pin or even a drill to mark the template's outline to its other side if you want to get a good fit and if your stand/branch is not very symmetrical.

Mine (my stand branch) was pretty symmetrical so I did not notice that the template was actually the mirror image of the outline when it is applied in to the bottom of the feet in the next step.

Feet: Tape Template to Bottom of Feet (2 Min)

Position the template on the bottom of the feet, straddling the feet crack (hee hee). You'll want this to be as centered as possible as this is eventually where the stand will go.

Tape down the template when the best position is found.

NOTE:

As mentioned in the previous step, the template is actually upside down here, so unless your stand branch is pretty symmetrical, you'll actually want to either put the template on top of the feet (rather than the bottom) OR puncture holes in the template and then flip it when placing it as in the photo on the bottom of the feet OR ignore this and just continue anyway.

Tape down the template when the best position is found.

NOTE:

As mentioned in the previous step, the template is actually upside down here, so unless your stand branch is pretty symmetrical, you'll actually want to either put the template on top of the feet (rather than the bottom) OR puncture holes in the template and then flip it when placing it as in the photo on the bottom of the feet OR ignore this and just continue anyway.

Feet: Drill Along the Template (7 Min)

Using a drill and 1/8' bit (or larger), drill holes all the way through the feet along the outline of the template.

Yes, you'll want to drill all the way through the feet and out the top of the feet.

Yes, you'll want to drill all the way through the feet and out the top of the feet.

Feet: Template Drilling Complete

When finished drilling through the template, your feet should look something like this.

Feet: Remove Template and Braces (2 Min)

Remove the template and the cross braces from the back of the feet.

In this photo I had to use a cat's paw to remove the stupid nails from the nail gun that I had used for the braces. This was tedious. <sigh>

In this photo I had to use a cat's paw to remove the stupid nails from the nail gun that I had used for the braces. This was tedious. <sigh>

Feet: Clamp to Workbench (2 Min)

Clamp one of the feet, bottom side down to a bench or edge of a deck.

Feet: Saw Out Template Marked Area (5 Min X 2)

Using a jig saw, cut along the template marks up to the edge of your workbench (or deck edge).

Feet: Complete Half Circle Cut Out (5 Min X 2)

Flip the foot around and continue cutting the other quarter of the template.

Repeat for the other footing.

Repeat for the other footing.

TIP: Watch Out When Cutting to an Edge ($#!&)

Sigh.

Wait for my next Instructable, "How to repair a deck edge ruined by a jig saw".

Wait for my next Instructable, "How to repair a deck edge ruined by a jig saw".

Feet: Trim the Cut Out (7 Min X 2)

Trim out the cut out area of the feet if they are pretty rough.

TIP: Dremel Chuck

Buy one of these immediately; it allows you to switch bits/tools without the wrench.

Feet: Sand (20 Min)

Sand the feet now while they are separate.

Feet: Position Together With Hole

Put the feet together again with the hole whole.

Feet: Trace Plywood Feet Shoes (7 Min)

Put a piece of plywood under the feet and insert the stand into the hole, position the feet and stand into the best position.

Trace the shape of the feet onto the plywood.

Trace the shape of the feet onto the plywood.

Feet: Registration Marks (2 Min)

While you have it all together, place a piece of tape on the stand and the feet and make a registration mark at the joint.

Why?

Since the stand is not perfectly round it will only fit into the feet hole a certain way. Making these registration marks will help to re-insert the stand at the same location at a later time.

Why?

Since the stand is not perfectly round it will only fit into the feet hole a certain way. Making these registration marks will help to re-insert the stand at the same location at a later time.

Feet: Registration Mark, Cont.

Repeat on the other side.

Feet: Cut Out Feet Shape of Plywood (10 Min)

Take the plywood and cut out the feet shape as close as possible.

Why?

Since the feet are not perfectly straight, the plywood will help keep them stable.

Why?

Since the feet are not perfectly straight, the plywood will help keep them stable.

Feet: Clean Up Plywood Shoe (10-20 Min)

We professional woodworkers have an expression: "Measure once, cut thrice. After than, trim it and shim it."

Due to quantum mechanics, whenever you use a jig saw, and no matter how accurate you cut, the result will never be correct.

That is why they invented the Dremel tool.

So trim the plywood back to fit the feet.

Due to quantum mechanics, whenever you use a jig saw, and no matter how accurate you cut, the result will never be correct.

That is why they invented the Dremel tool.

So trim the plywood back to fit the feet.

Feet: Glue Shoe to Bottoms of Feet (3 Min + Dry Time)

Glue the plywood shoe to the bottom of the feet.

You can use the registration marks to double-check that the feet are in the same position relative to the stand, then remove the stand.

Let the glue dry.

Go have yourself an alcohol bath while it dries. hee hee

You can use the registration marks to double-check that the feet are in the same position relative to the stand, then remove the stand.

Let the glue dry.

Go have yourself an alcohol bath while it dries. hee hee

Feet: Sigh More Trimming (20 Min)

sigh

Quantum mechanics will again play tricks on you.

Here I had to trim yet again after the glue had dried.

Quantum mechanics will again play tricks on you.

Here I had to trim yet again after the glue had dried.

Feet: Glue Plywood Shoe to Stand (5 Min + Dry Time)

Put glue on the plywood shoe hole, place the stand back into the shoe hole, line up the registration marks.

Let the glue dry and go have another alcohol bath. This is why woodworking is such an enjoyable profession.

Let the glue dry and go have another alcohol bath. This is why woodworking is such an enjoyable profession.

Feet-to-stand: Reinforce With Screws (7 Min)

Reinforce the shoe-to-stand by drilling screws through the bottom of the shoe into the stand.

Pre-drill a few 1/8 inch holes for the screws (see yellow text).

Use a 5/16 drill bit and drill down about 1/4 inch to create a "dimple" on top of the pre holes (see magenta text).

Drill in 2.5 inch or longer #8 deck screws. By drilling a dimple, the screw head will sink flush with the shoe bottom.

Pre-drill a few 1/8 inch holes for the screws (see yellow text).

Use a 5/16 drill bit and drill down about 1/4 inch to create a "dimple" on top of the pre holes (see magenta text).

Drill in 2.5 inch or longer #8 deck screws. By drilling a dimple, the screw head will sink flush with the shoe bottom.

Feet-to-stand: Reinforce From Side (10 Min)

Optionally, you can also reinforce the stand-to-feet joint by screwing in to the side of the stand.

Here I pre-drilled 1/8 inch holes into the stand, then drilled a 5/16 inch counter-sink hole about 1/4 inch deep, and finally screwed in a 2.5 inch deck screw.

I plugged up the hole with a stick which will later be cut off and sanded flush.

Here I pre-drilled 1/8 inch holes into the stand, then drilled a 5/16 inch counter-sink hole about 1/4 inch deep, and finally screwed in a 2.5 inch deck screw.

I plugged up the hole with a stick which will later be cut off and sanded flush.

Stand-to-slab: Put Butt on to Stand

Flip the stand upright and position the butt carefully onto the top of the stand.

Ahem.

Use a level and adjust the left/right tilt of the table top.

Place shims under the stand top to hold the left/right level.

NOTE:

Here is a great Instructable with an alternative (and smarter) way to level off your table top once it is attached.

https://www.instructables.com/id/Jig-for-surfacing-with-a-router

Place shims under the stand top to hold the left/right level.

NOTE:

Here is a great Instructable with an alternative (and smarter) way to level off your table top once it is attached.

https://www.instructables.com/id/Jig-for-surfacing-with-a-router

Stand-to-slab: Level Front/back Axis (10 Min)

Repeat with the level going front to back.

Here you can see the shims placed to position the level level.

NOTE:

This will become very frustrating and you will be defying the laws of physics, but continue to shim and level.

Here you can see the shims placed to position the level level.

NOTE:

This will become very frustrating and you will be defying the laws of physics, but continue to shim and level.

TIP: Level Mnemonic

To help remember which way to tip the level to get the bubble straight, remember:

When the bubble tilts one way it REALLY wants to keep going, so tilt the level that way in order to get the bubble straight.

In other words, tilt the level in order to help the bubble try to escape.

Why remember this mnemonic?

Some time you may be using a level with one finger and holding a post, pole, or board with your other hand and don't have the luxury of tilting the level both ways to try to remember which way it has to tilt.

When the bubble tilts one way it REALLY wants to keep going, so tilt the level that way in order to get the bubble straight.

In other words, tilt the level in order to help the bubble try to escape.

Why remember this mnemonic?

Some time you may be using a level with one finger and holding a post, pole, or board with your other hand and don't have the luxury of tilting the level both ways to try to remember which way it has to tilt.

Stand-to-slab: Attach L-brackets (7 Min X 4)

Install L-brackets at the joint between the table top and the stand.

Stand-to-slab: Disguise L-brackets (optional)

The L-brackets are kind of ugly. You can just leave them and hope that your friends are not callous enough to peek under your butt (er well you know what I mean).

But I created another set of "feet"-like thingies and screwed them in to sort-of hide the brackets. Not sure if it looks better that way or not.

But I created another set of "feet"-like thingies and screwed them in to sort-of hide the brackets. Not sure if it looks better that way or not.

Table: Stain, Urethane Feet (7 Min + Dry Time)

Almost done.

Stain, urethane the feet.

Tip:

Use these cheese-pyramid thingies to hold up the table while you stain the feet. Helps keep your floor from getting stain on it.

Stain, urethane the feet.

Tip:

Use these cheese-pyramid thingies to hold up the table while you stain the feet. Helps keep your floor from getting stain on it.

Finally!

Enjoy your butt table !

Two Seconds Later . . . (2 Secs)

Ah, yes it is a real table, covered with crap in record time.

More Butt Stuff

Here's a butt moon.

For more stuff you can make from a tree, see:

https://www.instructables.com/id/What-to-do-With-a-Felled-Tree/

and

https://www.instructables.com/id/Dog-Leash-Hook-from-Tree-Branches/