Laser Engrave&Cut a Wooden Clock Dial

by thunderlaser-nolan in Workshop > Laser Cutting

52 Views, 2 Favorites, 0 Comments

Laser Engrave&Cut a Wooden Clock Dial

A clock is one of those everyday objects we often pay attention to. A wooden clock dial, in particular, adds a subtle sense of warmth. Laser engraving makes this kind of project simple and repeatable. With just a wooden board and a clean design file, you can create a clock dial that fits different styles, sizes, or environments. In this tutorial, we’ll go through the basic workflow step by step. It’s a straightforward process that works well whether you’re making one piece or several at a time.

Supplies

Machine Used

- Thunder Bolt 30W

Material Needed

- 3mm Plywood

Settings

Engraving

- Speed:500mm/s

- Power:20%

- DPI:350

Cutting

- Speed:10mm/s

- Max Power:25%

- Min Power:10%

Downloads

Place Your Material

Lay your wooden board flat on the laser bed. Make sure it sits evenly and is properly secured so it won’t shift during cutting.

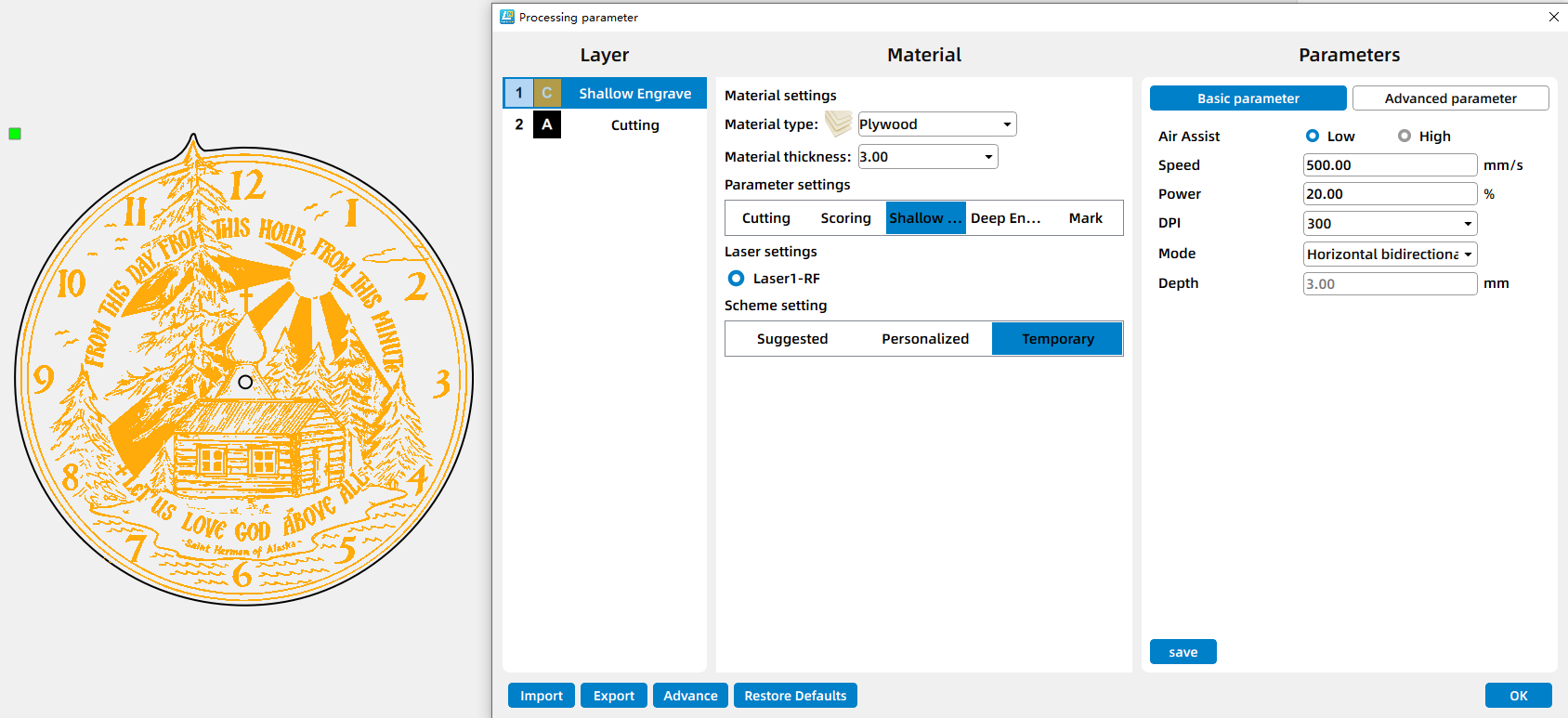

Open the Design and Check the Settings

Open your preferred laser software (I used Lasermaker) and load the clock dial design file. Adjust the size and positioning so it matches the area of your wood sheet.

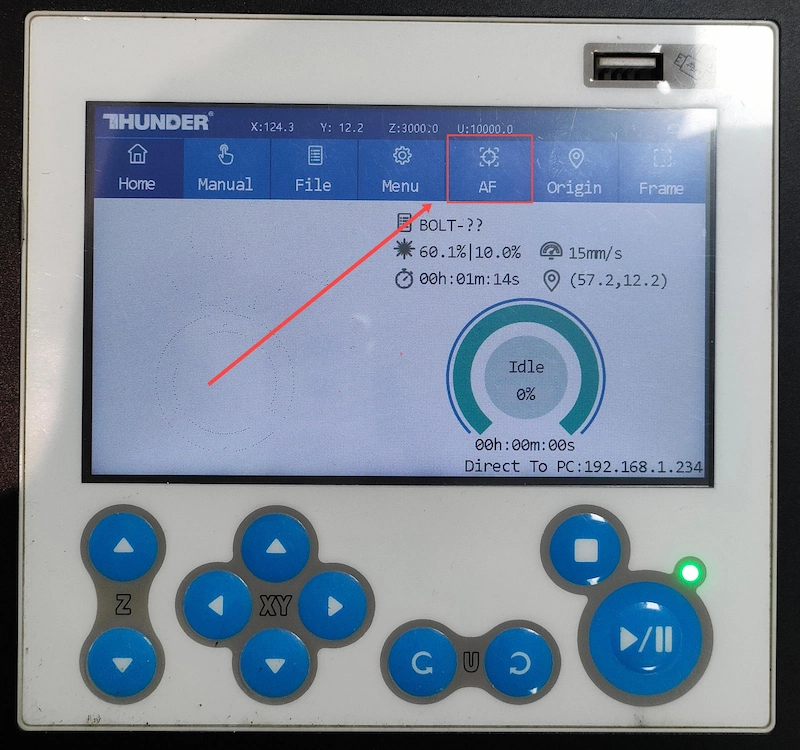

Focus Your Laser Machine

Proper focusing is essential for achieving crisp engravings and smooth cuts. If your machine supports auto focus, a single click will set the correct distance for flat wooden boards. If you prefer manual focus, use the focus stick to adjust the laser head until it just touches the surface of the wood at a perfect vertical angle. Spending an extra moment on accurate focusing will pay off with professional-looking results.

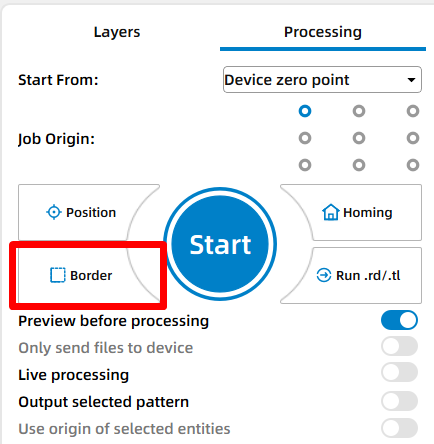

Frame the Design and Start Laser Engraving

Use the framing (Border) function to check the cutting area. This helps confirm that the design is positioned correctly and won’t exceed the material boundaries.

Monitor the Laser Engraving Process

Stay near the machine while it’s running and watch the cutting and engraving progress. Keep an eye out for excessive smoke, small flame-ups, or any movement of the material that could affect the outcome. Make sure your workspace is well-ventilated, and rely on air assist if available to achieve cleaner edges on the wood.

Install the Clock Hands

Once cutting is complete, remove the wooden dial from the laser bed. Insert the clock mechanism and carefully attach the hour and minute hands to the center of the dial.

Complete the Laser Task

Your laser-engraved wooden planet puzzle is now complete and ready to display. The natural wood grain gave the planets a warm, organic look, making the finished piece both playful and decorative.