How to Customize a Silver Ring With a Laser Machine

by thunderlaser-nolan in Workshop > Laser Cutting

64 Views, 0 Favorites, 0 Comments

How to Customize a Silver Ring With a Laser Machine

Want to turn an ordinary silver ring into a personalized keepsake?

This guide walks you through the process of using a laser marking machine to mark a silver ring with precision and style. Whether you’re creating custom wedding gifts, branded packaging, or simply adding a unique touch to your jewelry display, this guide will show you step-by-step how to achieve professional, long-lasting results on silver ring.

Supplies

Machine Used

Aurora Lite

Material Needed

Silver Ring

Settings

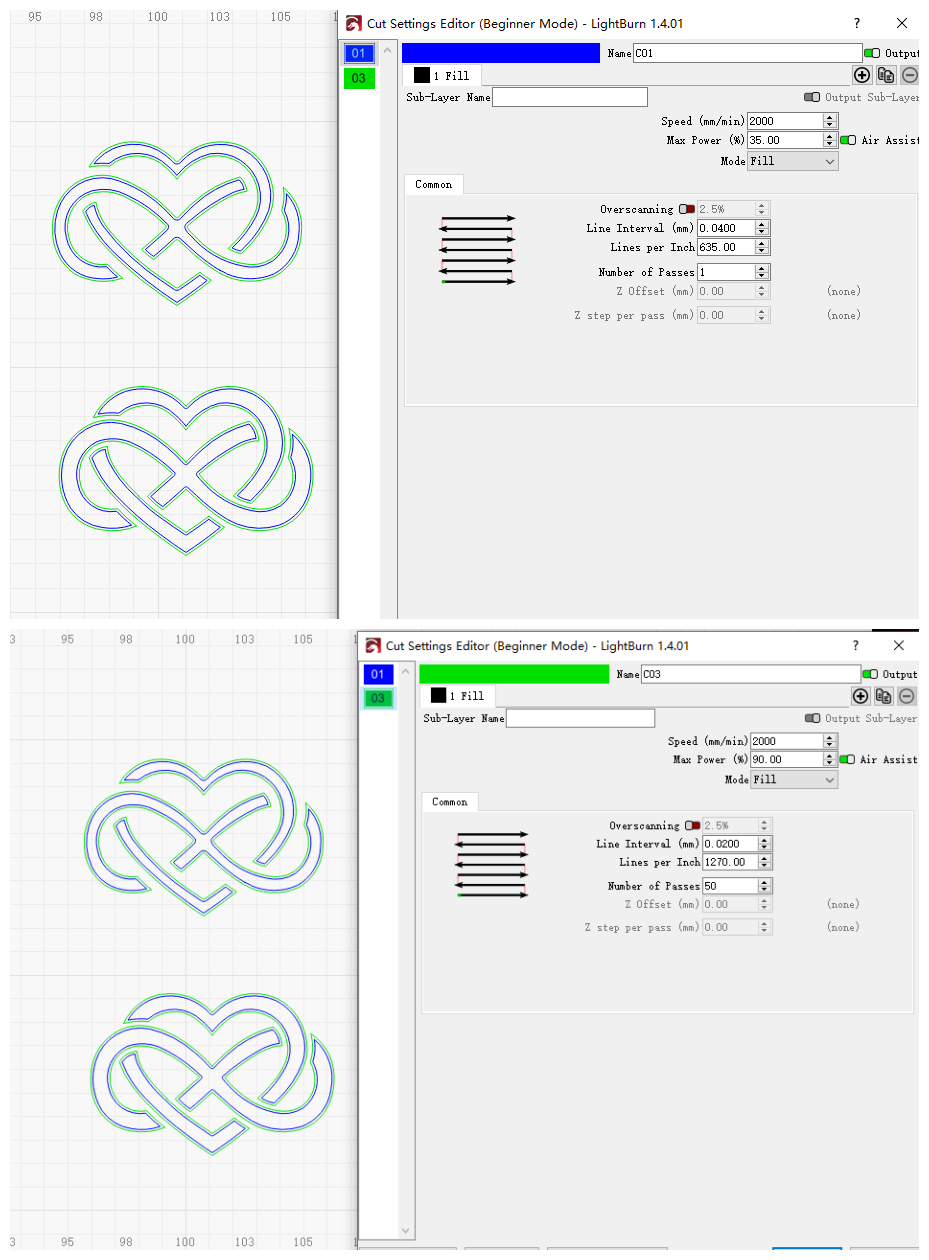

Laser Marking 1

- Speed:2,000mm/s

- Power:36%

- Frequency: 50kHz

- DPI:635

Laser Marking 2

- Speed:2,000mm/s

- Power:90%

- Frequency: 50kHz

- DPI:1270

Downloads

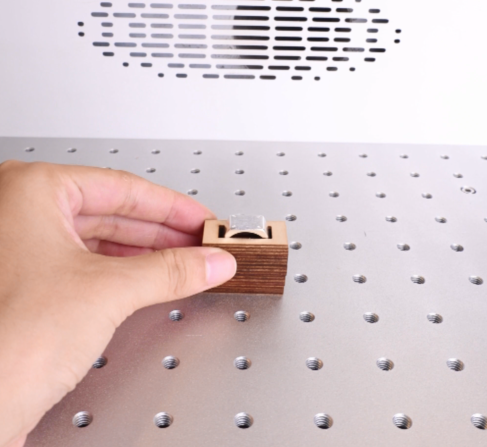

Place the Silver Ring

Because rings are small and hard to stablize during marking, so it’s better to use a custom jig or clamp to hold the ring securely in place. If you are engraving a round ring, a rotary attachment (rotary axis) is essential to ensure even and continuous marking around the curved surface.

Tip: Make sure the ring is level and tightly fixed. Any movement, even a fraction of a millimeter, can lead to misaligned or distorted engraving.

Import Your Ring File and Confirm the Laser Marking Settings

Open your preferred laser software (e.g., LaserMaker or LightBurn) and import your design file (SVG, DXF, or image). Adjust the size, rotation, and position of the design to match the exact area you want to engrave on the ring. Then make sure the laser marking parameters are set correctly.

Tip: Always double-check your design dimensions in the software to ensure they match the actual marking area. Use the “preview” or “frame” option to avoid accidental misplacement.

Focus Your Machine

Focus is the key to success. Once focus is ignored, the results may not be satisfying. Before you start, make sure you have finished focusing. With the Aurora Lite, you have two ways to achieve perfect focus. The first method uses the red-dot pointer to assist—simply adjust the laser head until the two red dots overlap, and you’re good to go. The second method, which is often more precise, is manual focusing with a focus stick. Adjust the height of the laser head until the focus stick just touches the surface of the material in a perfectly vertical position. Whenever possible, use manual focus for better accuracy.

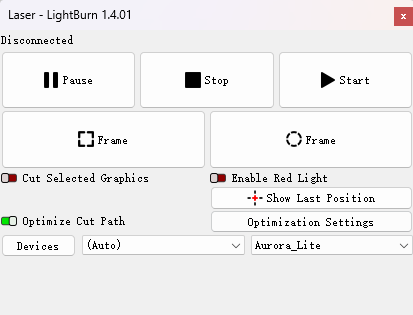

Frame the Design and Start Laser Marking

When we click the “Frame” , we can see red light show the outline of marking area. It’s safe, and the frame will be on the surface of the ring. Once it isn’t, move your ring or design until they are at the same position.

Once everything is adjusted, simply hit ‘Start’ to begin laser marking the ring with the Aurora Lite.

Monitor the Laser Marking Process

Keeping an eye on the machine allows you to spot unusual conditions—such as error alarms, smoke build-up, or unexpected pauses—before they become problems.

While observing, remember that the laser beam is extremely powerful. Even with the protective lid closed, avoid staring directly at the marking spot for too long. A quick glance to check progress is fine, but prolonged gazing should be avoided for safety reasons.

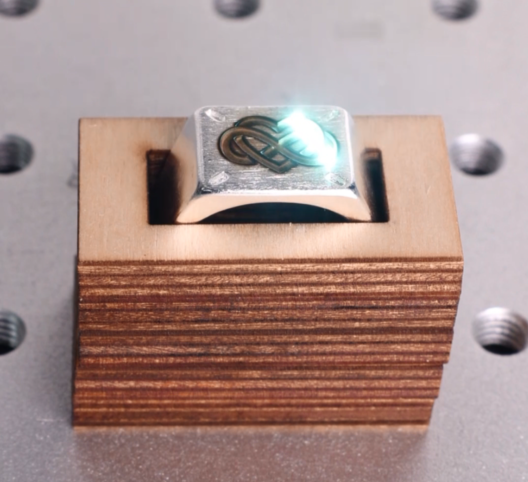

Complete the Laser Marking

Once the marking is complete, wait a few seconds before opening the machine lid to let any residual fumes dissipate. Carefully remove the silver ring and inspect the marking. If there’s any surface residue or dust, gently wipe it off with a soft, dry cloth.

Now it’s your turn! Get ready with your silver ring, fire up your Aurora Lite, and start creating your own personalized masterpiece. We’d love to see what you come up with—share your results and let’s inspire each other!