Pico Thermostat Display

by JeremiahJ28 in Circuits > Raspberry Pi

330 Views, 0 Favorites, 0 Comments

Pico Thermostat Display

This project is a mini thermostat using a Raspberry Pi Pico 2W, a DHT11 sensor, and an SSD1306 OLED display. It reads the current temperature and humidity and displays them in real-time. It’s a great intro to environmental sensing and IoT projects.

Supplies

Materials List

- Raspberry Pi Pico 2W

- DHT11 Temperature & Humidity Sensor

- SSD1306 OLED Display (128x64, I2C)

- Jumper wires

- MicroUSB dongle

- Breadboard (for prototyping)

- Custom 3D-printed enclosure (STL included)

- Soldering tools (for final build)

- Hot Glue

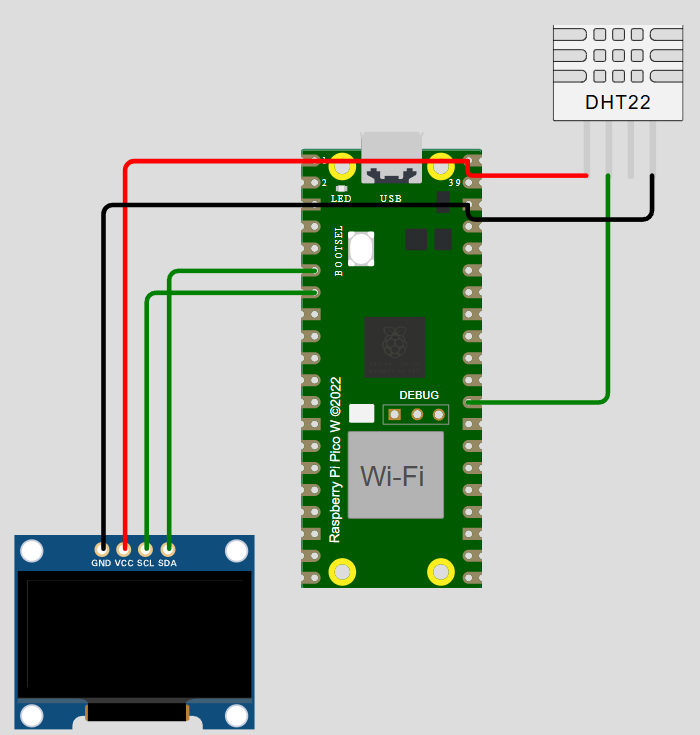

Design the Circuit

Step 1: Design the Circuit (WOKWI)

- Open the WOKWI project: Click Here

- Review the pin connections:

- DHT11 to GPIO 15

- SSD1306 (SCL to GPIO 1, SDA to GPIO 0)

- Power and ground appropriately wired

Flash the Code to Pico

Step 2: Flash the Code to Pico

- Install Thonny IDE

- Connect your Pico via USB

- Upload the MicroPython code (see code section below)

- Verify temperature and humidity readings appear on the display

I am unable to upload the font files with current extention (.pf) So I have renamed them to (.txt)

You will need to rename them back for it to work properly

Breadboard

Test everything on the breadboard first

Print the Enclosure

Step 3: Print the Enclosure

- Print the custom STL file provided

- Snap-fit the Pico, sensor, and display into the case

- I used the soldering Iron to melt the mounts for the OLED so they were a snug fit

- The Pico fits loosely...once I had wiring figured out I dropped a drop of Hot Glue behind teh pico when fitting it into teh case

- You can do either with the sensor, I made the mount long enough to melt, but I opted to put hot glue under mine.

Final Assembly

Step 4: Final Assembly

- Solder connections for a more permanent build

- Mount components securely in the case

- Power using USB and test the display

Reflection

Reflection

- Challenges: Sizing the STL properly to allow wires to pass through and accommodate the display.

- Lessons Learned: How to read from a sensor, display data, and prototype before printing.

- Improvements: Could add buttons to set a temperature threshold and trigger an alert.

- Future Plans:

- Building a few of these that will then use teh wireless function to communicate with a MASTER Pi who will then control the valves to allow heating to each room that requires it

- Including a waterproof one for the Hot Tub and Pool

- Monitoring a Chest Freezer temperature